150--180 Kg/H

Sawdust Continuous Carbonization Furnace adopts advanced hot air carbonization process technology.

Sawdust Continuous Carbonization Furnace adopts advanced hot air carbonization process technology which greatly increases carbonization ratio (increased from about 88% to 99%) and shortens the carbonization time, The carbonization time just within 4 hours. higher safety and efficiency, energy saving and environmental protection.

Sawdust Continuous Carbonization Furnace increased the flue gas recovery unit based on the original carbonizer,can get clean smokeless after flue gas recycling,the recycled gas can be used to heating,aslo can be used for the drying machine.

Raw Materials:

wood sawdust, rice husk etc.

Features:

1.Production sustainable;

2.Closed cooling;

3.Carbonization temperature is adjustable;

4.High heat transfer high wear resistant composite material form efficient carbonization chamber;

5.All gas return furnace combustion use no exhaust pollution

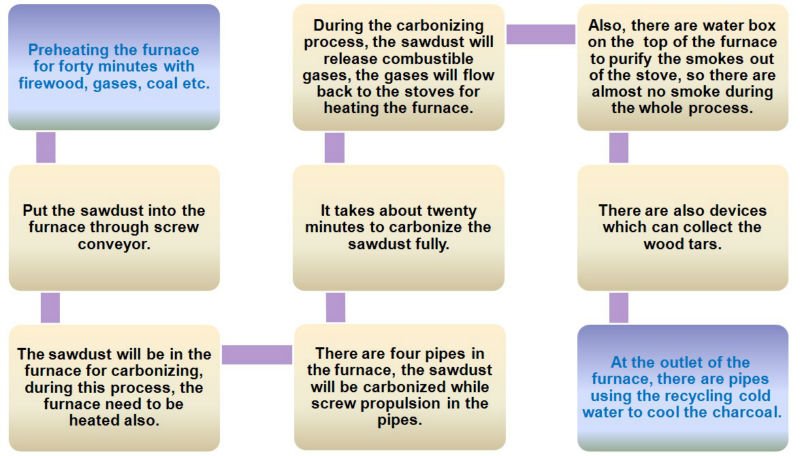

This Sawdust Continuous Carbonization Furnace is the ideal equipment to carbonize the sawdust or wood chips. Our factory has got the patent on this furnace, and has sold many to foreign countries, such as: Lebanon, Zambia, France etc. Following is the detailed working process: