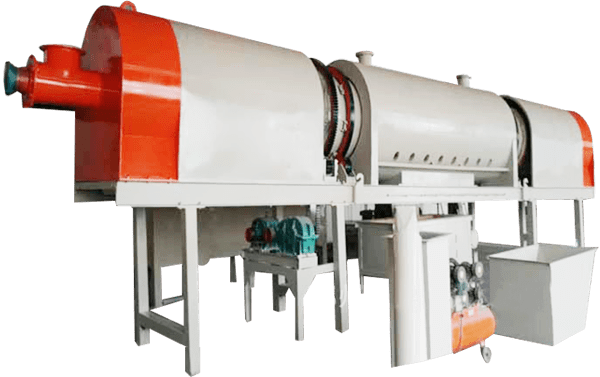

A continuous carbonization furnace is a device used to convert organic matter into carbonaceous products. This kind of carbonization furnace adopts the working mode of continuous feeding and continuous discharge, so that the carbonization process can be carried out continuously, thereby improving the production efficiency.

Continuous carbonization furnace usually consists of the following main parts:

Feeding system: The feeding system is used to continuously feed raw materials into the carbonization furnace. Raw materials can be various organic substances, such as wood, straw, plant residues, etc. The feeding system usually includes feeding conveyor belts, feeders and other equipment to ensure continuous supply of raw materials.

Carbonization chamber: The carbonization chamber is the core part of the carbonization furnace, which is used for carbonization reaction. In the carbonization chamber, raw materials are exposed to a high temperature environment and converted into carbonaceous products through pyrolysis and gasification reactions. The carbonization chamber is usually constructed of high temperature resistant materials and has good heat insulation performance.

Heating system: The heating system is used to provide the high temperature required by the carbonization chamber. Common heating methods include electric heating, natural gas heating, or biomass combustion heating. The heating system can ensure the effective carbonization process by controlling the heating temperature and time.

Flue gas treatment system: The carbonization process will produce a large amount of flue gas and volatiles. In order to reduce environmental pollution and use energy efficiently, continuous carbonization furnaces are usually equipped with flue gas treatment systems. The system usually includes dust removal equipment, coolers and exhaust gas treatment devices to purify the flue gas and recover energy.

Control system: The continuous carbonization furnace is usually equipped with a control system for monitoring and controlling various parameters of the carbonization process. Operators can set carbonization temperature, feed rate and other parameters through the control panel or interface, and monitor the operation status of the carbonization process.

The advantages of continuous carbonization furnaces include high efficiency, continuous production, energy saving and pollution reduction. They can be applied in wood processing, biomass energy production, and crop waste treatment to convert organic matter into high-quality carbon products such as charcoal, biochar, etc.

It should be noted that specific models and manufacturers may have different designs and features, so when selecting and operating a continuous carbonization furnace, you should refer to the relevant equipment instructions and usage guidelines.

Zhengyang Charcoal Machine Home Page: http://www.zyfuelmachine.com/,All rights reserved.